The construction industry generates significant waste streams annually, up to 35% (Villoria Sáez and Osmani, 2019) of total waste generation. Reducing waste streams via recycling and material efficiency could reduce emissions and hinder the depletion of natural resources. ERDF funded RAPA project develops new methods to utilize construction and demolition waste to promote circular economy.

Geopolymers are generally adopted as a binder to establish a substance that possesses identical properties and composition as concrete. These aluminosilicate-based materials can match the durability, thermal and mechanical properties of conventional concrete formed with ordinary Portland cement, depending on the chemical formation of ingredients. Common precursors used in geopolymers are fly ash, blast furnace slag, and silica fume or metakaolin. All of these materials can be obtained from secondary sources as recycled raw materials. 3D printing of geopolymers for construction products includes digital modelling of structures which enables the minimization of material waste and reduces labor requirements. (Pérez et al. 2020; Tankova et al. 2020).

Sustainable concrete

The addition of aggregates to the geopolymer cement results in composite material called geopolymer concrete. Geopolymer concrete formulation without the adoption of cement makes geopolymers a sustainable alternative to Ordinary Portland cement (OPC). Globally, an acceleration in the volumes of solid waste from mining, construction, paper and pulp industries has presented a significant risk to the atmosphere and ecology. By and large, these wastes are disposed of on vacant land areas, producing not only a landfill crisis but also creates environmental pollution. Locally available recycled and waste materials contain aluminum and silicon considered a suitable recipe for geopolymer preparation.

![Geopolymer concrete has various sustainable advantages over conventional OPC, these are further discussed in the text.]](https://blogit.lab.fi/labfocus/wp-content/uploads/sites/8/2021/05/240_2021_3D-printing-of-recycled-construction-waste-into-geopolymer-products_1.png)

Geopolymers have high acid resistance and adhesion with steel, concrete, and iron. (Ueng et al. 2012), which makes them a viable substitute to OPC as an eco-friendly solution (Panda & Tan 2018).

Green buildings

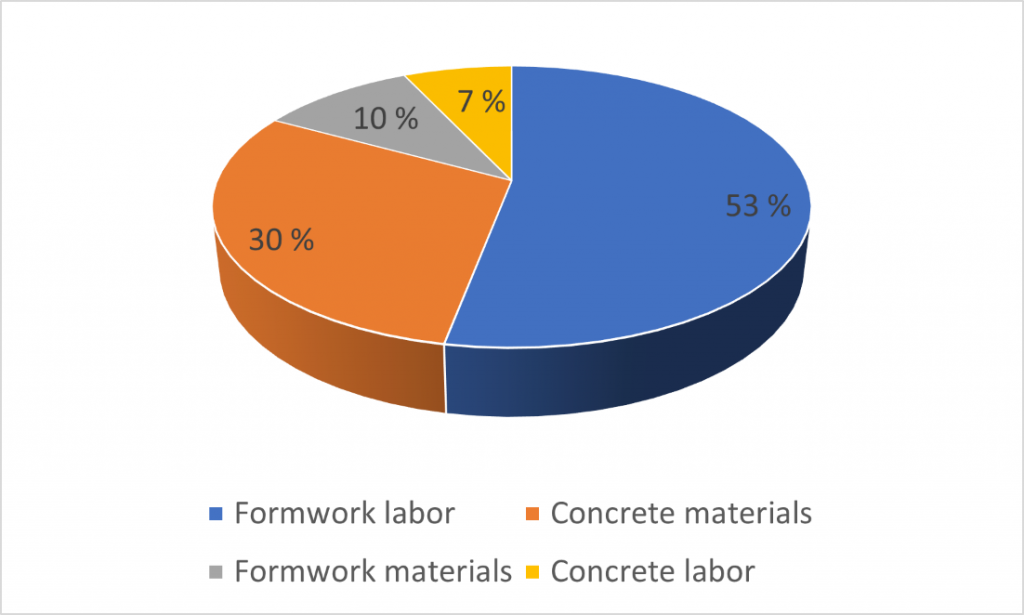

Traditional building and construction methods yield a huge amount of waste, as the moulds that are demanded casting the structures or details cannot be reused. Applying 3D printing techniques in the construction industry for constructing buildings offers a reduction in CO2 (carbon dioxide) emissions when the entire product life cycle is considered since the material use and waste can be lowered with the elimination of formwork.

Less waste is generated with 3D printing compared to conventional concrete working practices. This can promote sustainability even better when practiced simultaneously with geopolymers. Reduction of CO2 emissions in geopolymer cement production compared to OPC is in the range of 40% to 80-90% depending on the type of geopolymer cement. Furthermore, the energy need in the production of geopolymer cement can be 43-59% compared to OPC. (Davidovits 2013.)

Authors

Qaisar Munir works as junior researcher at LUT university of technology, working in RAPA project with the aim of low carbon products for construction and demolition waste.

Ville Puhakka works as project manager and RDI-specialist in RAPA project at LAB University of applied sciences. His main interests are circular economy, waste and water treatment.

References

Davidovits, J. 2013. Geopolymer cement. A review. Geopolymer Institute, Technical papers, 21, pp.1-11. [Cited 11 May 2021]. Available at: https://www.geopolymer.org/library/technical-papers/21-geopolymer-cement-review-2013/

Panda, B. & Tan, M. J., 2018. Experimental study on mix proportion and fresh properties of fly ash based geopolymer for 3D concrete printing. Ceramics International, Vol 44 (9), 10258– 10265. [Cited 11 May 2021]. Available at: https://doi.org/10.1016/j.ceramint.2018.03.031

Pérez, M., Carou, D., Rubio, E.M. and Teti, R., 2020. Current advances in additive manufacturing. Procedia Cirp, 88, 439-444. [Cited 11 May 2021]. Available at: https://doi.org/10.1016/j.procir.2020.05.076

Tankova, T. and da Silva, L.S., 2020. Robotics and Additive Manufacturing in the Construction Industry. Current Robotics Reports, 1(1), 13-18. [Cited 11 May 2021]. Available at: https://doi.org/10.1007/s43154-020-00003-8

Ueng, T.H., Lyu, S.J., Chu, H.W., Lee, H.H. and Wang, T.T., 2012. Adhesion at interface of geopolymer and cement mortar under compression: An experimental study. Construction and Building Materials, 35, 204-210. [Cited 11 May 2021]. Available at: https://doi.org/10.1016/j.conbuildmat.2012.03.008

Villoria Sáez, P., Osmani, M., 2019. A diagnosis of construction and demolition waste generation and recovery practice in the European Union. Journal of cleaner production. 241, 118400. [Cited 11 May 2021]. Available at: https://doi.org/10.1016/j.jclepro.2019.118400

Links

Link 1. LAB University of Applied Sciences. 2021. RAPA – Low-carbon products of construction and demolition waste reject. [Cited 11 May 2021]. Available at: https://lab.fi/en/project/low-carbon-products-construction-and-demolition-waste-reject

Pictures

Picture 1. Free photos 2016. Id-1081956. [Cited 11 May 2021]. Available at: https://pixabay.com/images/id-1081956/

Picture 2. Hassan, A., Arif, M. and Shariq, M., 2019. Use of geopolymer concrete for a cleaner and sustainable environment. A review of mechanical properties and microstructure. Journal of cleaner production. Volume 223, 704–728. [Cited 18 May 2021]. Available at: https://doi.org/10.1016/j.jclepro.2019.03.051

Picture 3. Paul, S. C., van Zijl, G. P. A. G., Tan, M. J. & Gibson, I. 2018b. A review of 3D concrete printing systems and materials properties: current status and future research prospects. Rapid Prototyping Journal, 24: 4. Pp. 784 798.