The Food Pilot Plant product development environment at LAB University of Applied Sciences has been enhanced with a Texture Analyser and a VolScan (Stable Micro Systems), which are used to investigate the textural properties of food products with the precision required for research. The equipment was purchased to support product development and research services of bakery industry, but it is widely applicable also to other food product types. With this equipment, it is possible to develop and study the textural properties of food products, from baked goods to sweets, protein products, snack bars, spoonable snacks, biscuits, cheeses, gels, pasta products, fruits, and snack products (Stable Micro Systems 2024). Product development and quality assurance can be notably assisted, as textural properties can be measured objectively, and the results can be compared over a long period of time. For instance, target values for hardness can be set for product texture, which are aimed for when a new product or new recipe is developed.

Texture Analyser

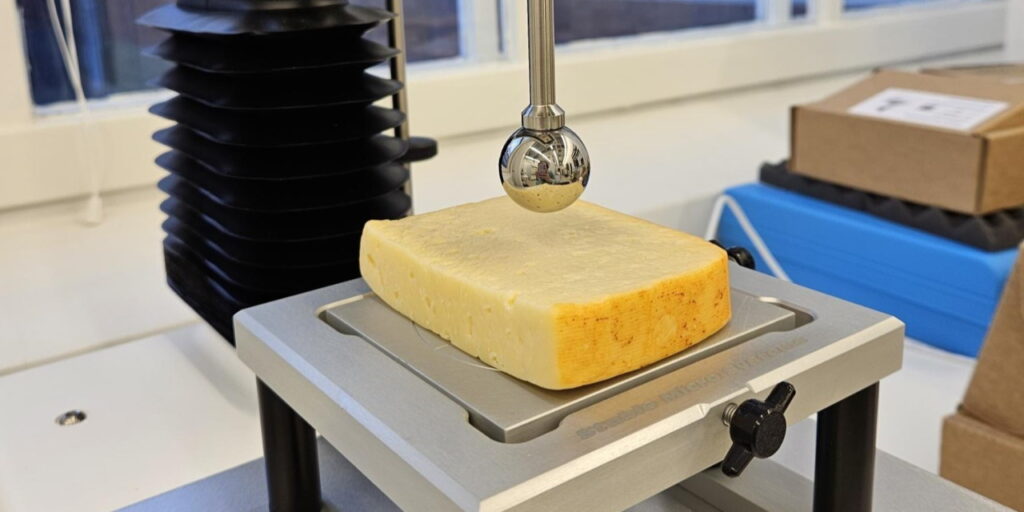

The Texture Analyser is used to analyse textural properties, such as hardness, elasticity, brittleness, flexibility, and ductility of the material. The equipment operates based on compression and tensile tests, which can be modified according to the material properties and the parameters desired to be measured. The tests can be used to determine, for instance, breaking point of a material or to understand how the material behaves when chewed.

The Food Pilot Plant’s Texture Analyser is equipped with a wide range of measuring probes to enable versatile analyses (Figures 1A and 1B). Ready-made and standard measurement programs are provided, which can be modified as needed, or completely new ones can be developed.

For example, a two-bite compression test (texture profile analysis, TPA) is often used to investigate crumb texture of bakery products. In TPA, a 36 mm diameter cylindrical probe compresses a 25 mm thick bread crumb sample twice to a deformation of 40% at a constant speed (Figure 2, Sammalisto et al. 2021). TPA simulates the chewing of the sample in the mouth (Texture Technologies 2024). The maximum force required for the first compression describes the hardness of the sample, and conclusions can be drawn from the measurement data of two compressions, for instance, about the recovery of the structure between compressions.

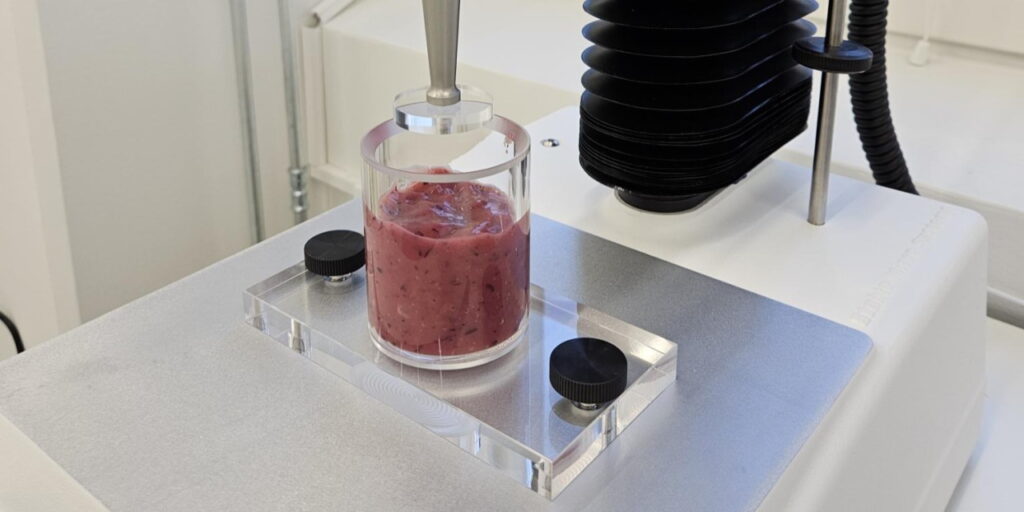

Additional equipment of Texture Analyser

Texture Analyser is equipped with backward (Figure 3) and forward extrusion sets, which enable analysing consistencies of viscous materials such as sauces, spoonable products, and doughs. For example, dough consistency determined using backward extrusion method has been reported to be related to the softness of the bread crumb structure in gluten-free oat baking (Sammalisto et al. 2021) and buckwheat baking (Pitkänen 2019).

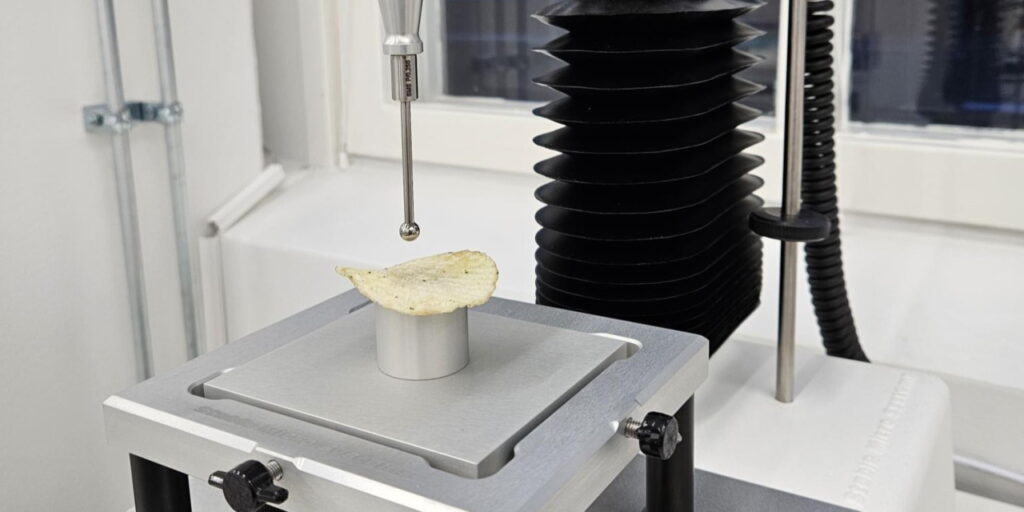

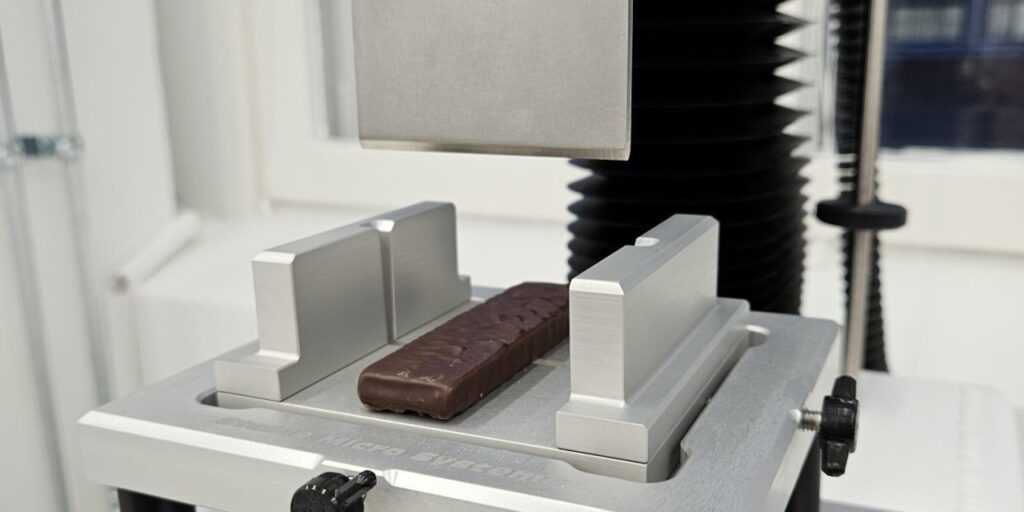

The Crisp fracture rig is suitable to monitor crispness of snack products, such as potato or rye chips, during recipe development, for instance (Figure 4A). The Blade set is used to measure the cutting force of a chocolate bar, which indicates the chew resistance of the material (Figure 4B).

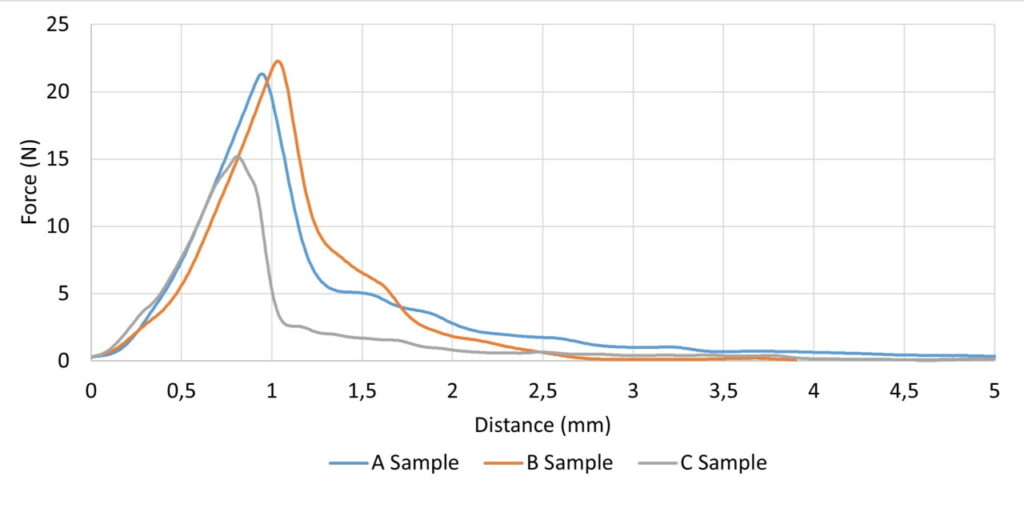

In Three point bend rig, a blunt blade cuts for example a crispbread, allowing the breaking point (or bending behaviour in the case of softer products) and the fragility of the structure to be monitored. Differences in breaking force and fragility of three commercial crispy products were examined, as shown in Figure 5.

In addition, a Kieffer test has been purchased to Food Pilot Plant. Kieffer’s test is used to determine extensibility properties of wheat dough (Smewing 2014).

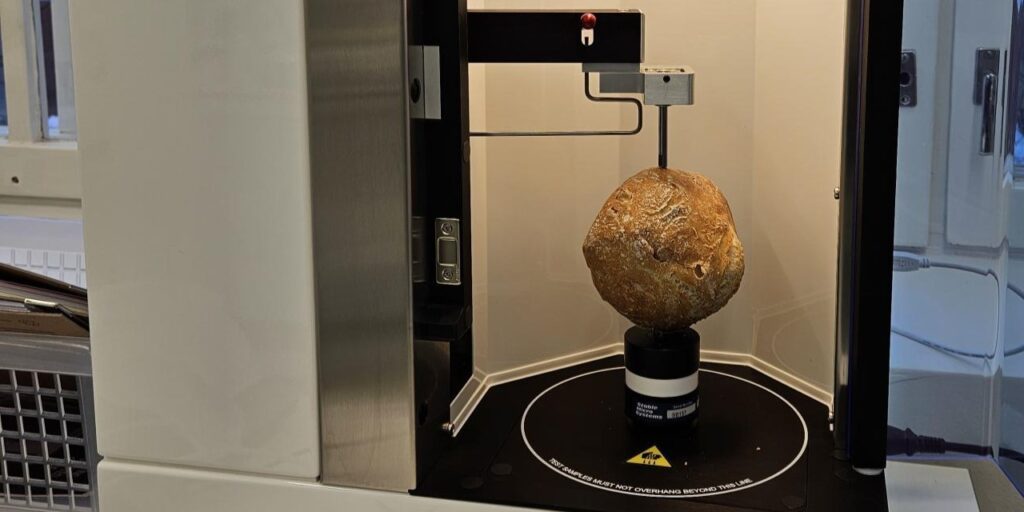

Volume Scanner

Volume scanner (VolScan Profiler, Figure 6) measures volume of a sample with laser, and a 3D image is drawn from the product (Stable Micro Systems, 2024a). The sample mass can be used to calculate the density and specific volume of the product. The equipment is suitable, for example, for product development of bakery and snack products to achieve a more aerated structure.

Author

Saara Sammalisto (Doctor of Food Sciences) works as a researcher at LAB University of Applied Sciences in the Food Pilot Plant product development environment. In her doctoral thesis, defended in the spring of 2024 at the University of Helsinki, she investigated the textural properties of doughs, oat breads, and milling products of oats.

References

Pitkänen P. 2019. Gluteenittoman taikinan konsistenssi ja leivontalaatu. Master’s thesis. University of Helsinki. EKT series 1884. Cited 3 Jan 2025. Available at http://hdl.handle.net/10138/309379

Sammalisto S., Laitinen M. & Sontag-Strohm T. 2021. Baking Quality Assessment of Twenty Whole Grain Oat Cultivar Samples. Foods. Vol. 10 (10), 2461. Cited 10 Dec 2024. Available at https://doi.org/10.3390/foods10102461

Smewing J. 2014. Texture Analysis in action: the Kieffer Dough and Gluten Extensibility Rig. Texture Analysis Professional Blog. Cited 10 Dec 2024. Available at https://textureanalysisprofessionals.blogspot.com/2014/12/texture-analysis-in-action-kieffer.html

Stable Micro Systems. 2024. Texture Analysis Application Areas. Cited 10 Dec 2024. Available at https://www.stablemicrosystems.com/TextureAnalysisApplications.html#food

Texture Technologies. 2024. Texture Profile Analysis. Cited 10 Dec 2024. Available at https://texturetechnologies.com/resources/texture-profile-analysis