This LAB Technology Summer Internship project was undertaken to explore and utilize the capabilities of the Roland Modela Pro II MDX-540 CNC milling machine in combination with SolidWorks CAM software. When used with a CNC machine, the CAM software generates machining instructions (NC code) for the machine to interpret and follow.

The project’s primary objective was to effectively implement the process of transferring NC code generated using SolidWorks CAM to the milling machine and performing machining on a workpiece using the generated code. The subsequent goal was to create a comprehensive tutorial for users unfamiliar with the SolidWorks CAM and Roland milling machine. This article outlines this project as part of the LAB Technology Summer Internship during the summer of 2023.

Testing and machining features created using SolidWorks CAM

The team has identified and selected common features typically found in part designs, as well as useful capabilities of the machine. After that, tests were conducted by machining a plastic workpiece. Such features as part contour, holes, fillets, machining with multiple tools from the tool crib, machining with rotation of the A-axis, engraving, and other features and capabilities have been tested during the project. As a result of the practice, our team developed an understanding of the machine, its operation, code input procedure, and the execution of machining. The process of working with the Roland milling machine is depicted in Image 1.

Tutorial development

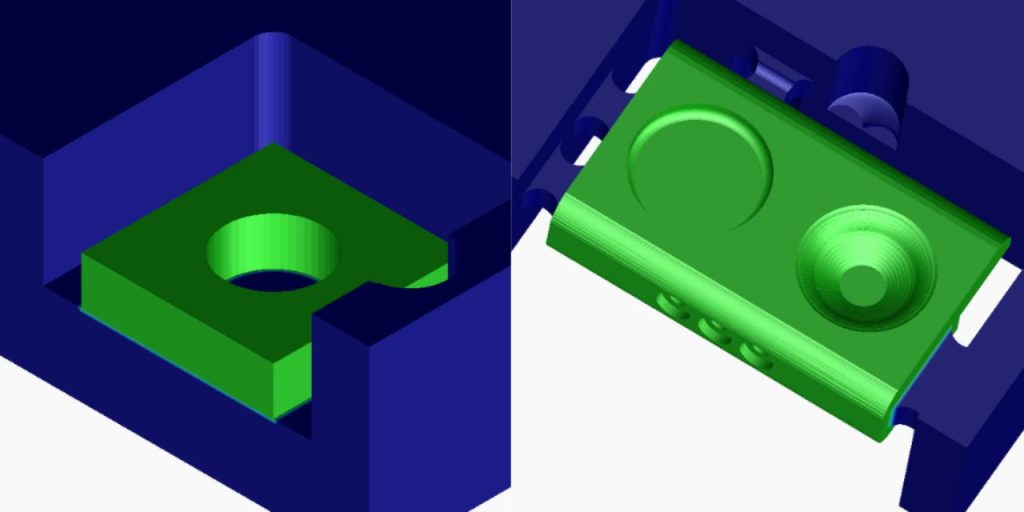

After experimentation with the machining features, efforts were directed toward developing a tutorial. Two demonstration parts (Image 2) were modeled using SolidWorks software as part of the tutorial development. The demonstration parts were successfully machined from plastic to assess the feasibility and identify potential errors.

The structure of the tutorial includes four primary sections: Introduction, Exercise 1, Implementation of NC code to Roland MDX-540, and Exercise 2. Key aspects of each section, excluding the introduction, have been incorporated as subsections to enhance both navigation and comprehension for the readers. The team has also produced tutorial videos to assist the users with step-by-step guidance for both exercises. Link to the tutorial videos on YouTube.

Learning outcome

The project has granted us hands-on experience in CNC machining and valuable insights into SolidWorks CAM software. Documenting procedures and creating the tutorial enhanced our ability to communicate and provide instructions in a technical context.

Authors

Aleksandra Sennikova is a Mechanical Engineering student at LAB University of Applied Sciences and a participant in the LAB Summer Internship.

Juuso Miettinen is a Mechanical Engineering student at LAB University of Applied Sciences and a participant in the LAB Summer Internship.

Eero Scherman is a Senior Lecturer at LAB University of Applied Sciences in Mechanical Engineering and the coordinator for this specific task in LAB Technology Summer Internship 2023.

Links

Link 1. Juuso Miettinen. 2023. Implementation of SOLIDWORKS CAM to Roland milling machine Tutorial. Uploaded 27 Aug 2023. Cited 10 Sep 2023. Available at https://www.youtube.com/playlist?list=PLCJxwAir8RmU8h0UGMw6F5R78URLijpvV